Explosion-Proof Corrosion-Resistant Double Push Button ZXF8030

| Rated Voltage | Rated Current | Explosion-Proof Marking | Protection Rating | Corrosion Resistance Rating | Cable Outer Diameter | Inlet Thread |

|---|---|---|---|---|---|---|

| AC 220V/380V | 10A, 16A | Ex db eb IIC T6 Gb Ex tb IIIC T80°C Db |

IP66 | WF2 | Φ10~Φ14mm | G3/4" |

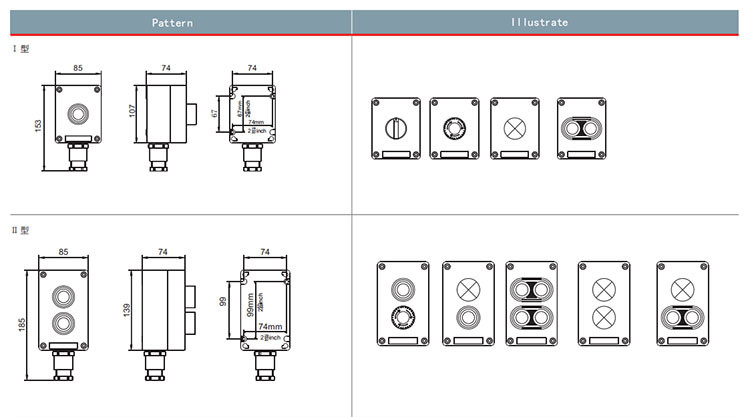

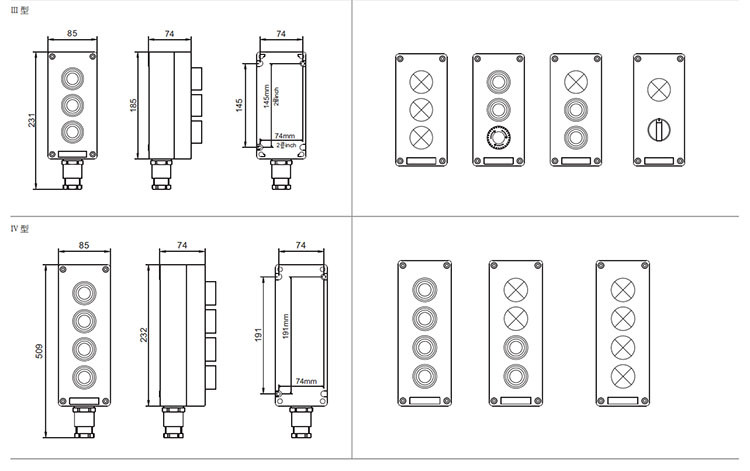

1. The enclosure is constructed from glass fiber reinforced unsaturated polyester resin molding or high-grade stainless steel welding, offering corrosion resistance, anti-static properties, impact resistance, and excellent thermal stability;

2. Exposed stainless steel fasteners provide superior corrosion resistance;

3. This series employs enhanced safety enclosures housing explosion-proof components such as indicator lights, pushbuttons, and selector switches;

4. The curved-seal design between housing and cover ensures excellent waterproofing and dust resistance;

5. Internal components can be freely arranged according to user specifications;

6. Compatible with both conduit and cable wiring.

1. Suitable for Zone 1 and Zone 2 locations in explosive gas environments;

2. Suitable for Class IIA, IIB, and IIC explosive gas environments;

3. Suitable for Zone 21 and Zone 22 locations in explosive dust environments;

4. Suitable for Class IIIA, IIIB, and IIC explosive dust environments;

5. Suitable for temperature classes T1 to T6;

6. Suitable for hazardous environments in petroleum extraction, refining, chemical processing, military applications, offshore oil platforms, tankers, defense industries, metal processing, and similar settings