Explosion-Proof Circuit Breaker BZD52

GB/T3836.1、GB/T3836.2、GB/T3836.3、GB/T3836.31、IEC60079-0、IEC 60079-1、IEC 60079-7、IEC 60079-31

| Model Specifications | Rated Voltage (V) | Rated Current (A) | Explosion-Proof Marking | Protection Rating | Corrosion Resistance Rating | Cable Entry Thread | Cable Outer Diameter |

|---|---|---|---|---|---|---|---|

| BDZ52 | AC 690V,660V,440V,400V,380V, 230V,220V,110V,48V,36V,24V,12V DC 220V,110V,48V,36V,24V,12V |

In≤16 | Ex db eb IIB T6 Gb, Ex tb IIC T80℃ Db |

IP66 | WF1 WF2* |

G3/4"~G4" | Φ10~Φ80mm |

| 63<In≤100 | Ex db eb IIB T5 Gb, Ex tb IIC T80℃ Db |

||||||

| 100<In≤630 | Ex db eb IIB T4 Gb, Ex tb IIC T80℃ Db |

||||||

| BDZ53 | In≤16 | Ex db eb IIB T6 Gb, Ex tb IIC T80℃ Db |

|||||

| 63<In≤100 | Ex db eb IIB T5 Gb, Ex tb IIC T80℃ Db |

||||||

| 100<In≤630 | Ex db eb IIB T4 Gb, Ex tb IIC T80℃ Db |

| Model Specifications | Rated Current (A) | Inlet Thread | Cable Outer Diameter |

|---|---|---|---|

| BDZ52 BDZ53 |

In≤16 | G3/4" | φ10~φ14mm |

| 16<In≤32 | G1" | φ12~φ17mm | |

| 32<In≤40 | G1 1/4" | φ15~φ23mm | |

| 40<In≤63 | G1 1/2" | φ18~φ33mm | |

| 63<In≤160 | G2" | φ26~φ43mm | |

| 160<In≤200 | G2 1/2" | φ30~φ50mm | |

| 200<In≤315 | G3" | φ38~φ57mm | |

| 315<In≤630 | G4" | φ48~φ80mm |

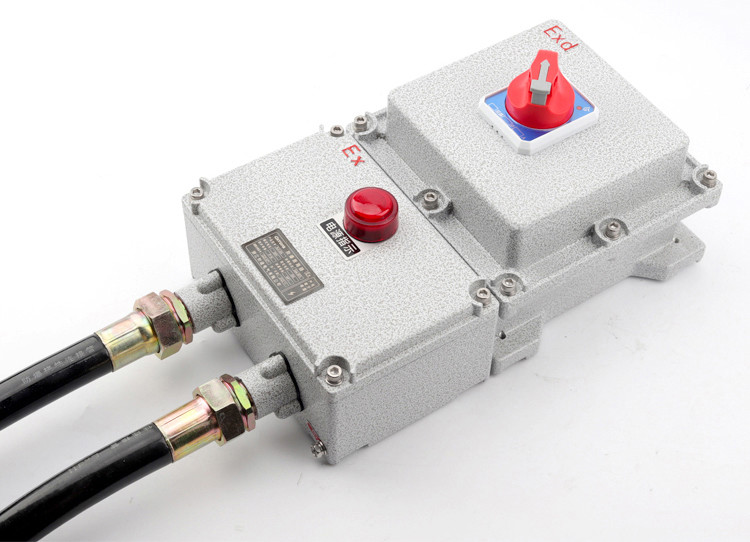

1. Aluminum alloy die-cast housing undergoes high-speed shot blasting followed by high-pressure electrostatic powder coating for corrosion resistance and aging resistance;

2. Stainless steel exposed fasteners provide superior corrosion resistance;

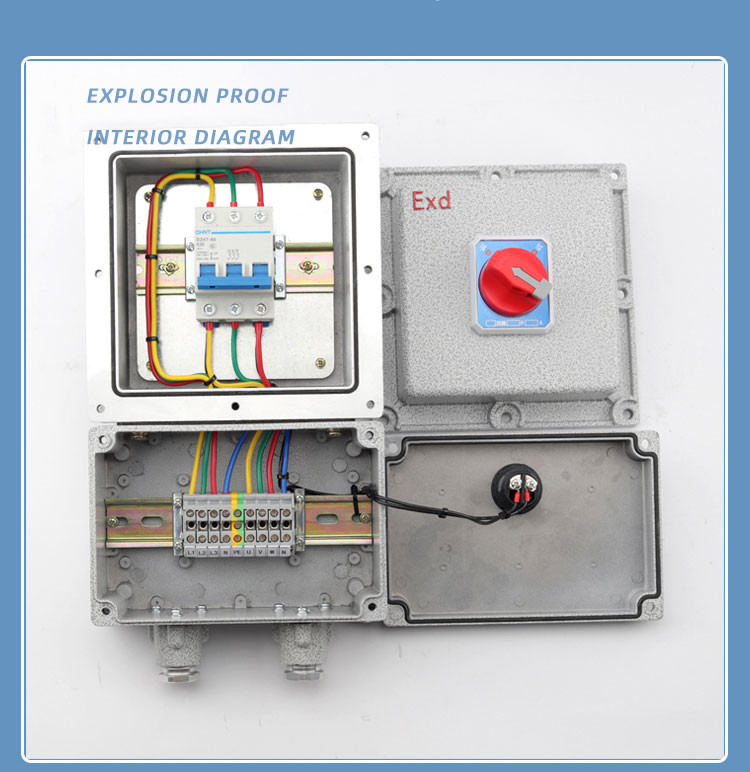

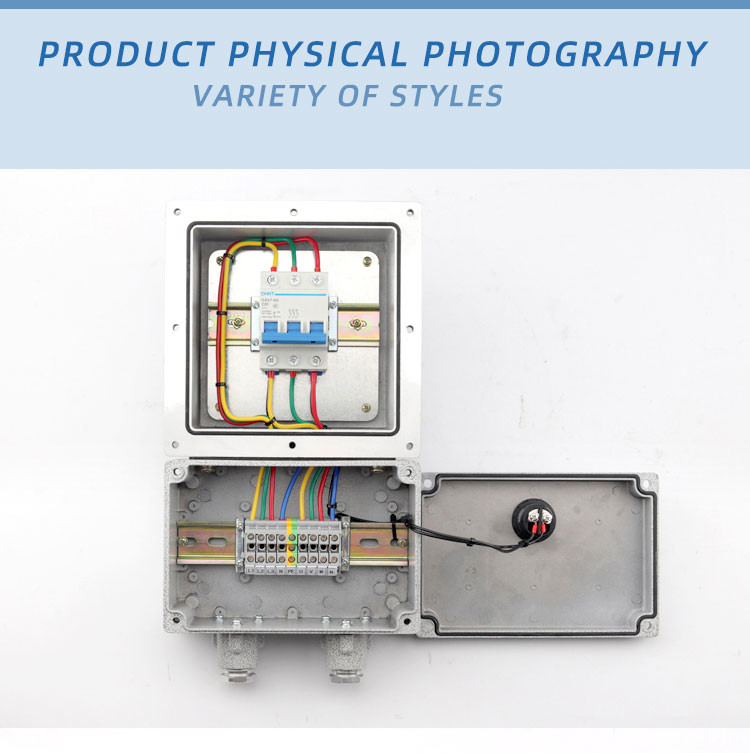

3. This series features a composite structure: the main chamber employs explosion-proof construction (IIB type with flat-face explosion-proof, IIC type with flanged explosion-proof), while the wiring chamber uses increased safety construction;

4. Equipped with high-breaking capacity miniature circuit breakers or molded case circuit breakers. The cover features a PC operating handle with a patented new mechanism, offering a simple, rational design, high versatility, and convenient operation;

5. Sealing strips utilize advanced one-step wire-pour foaming molding technology for superior protection;

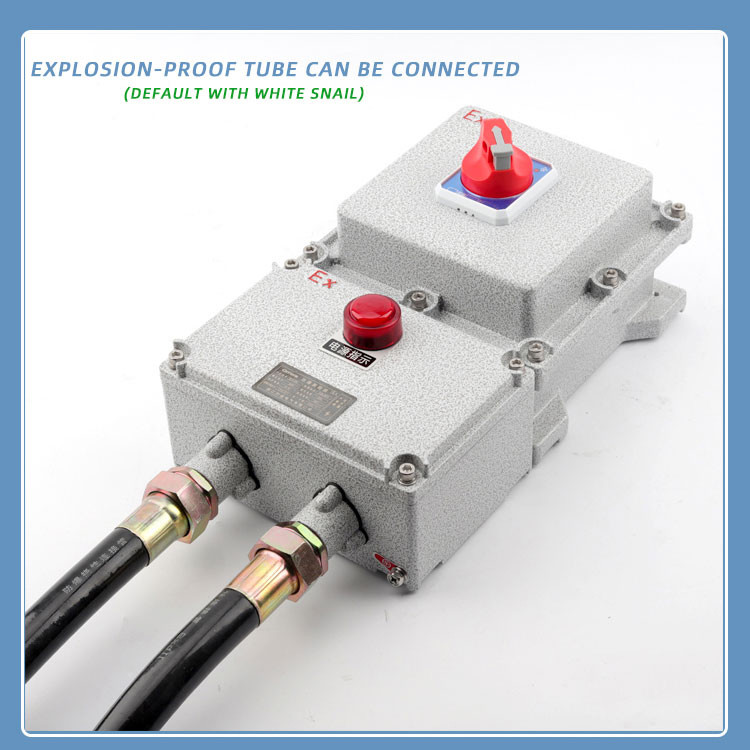

6. Compatible with both steel pipe and cable wiring.

1. Suitable for Zone 1 and Zone 2 locations in explosive gas environments;

2. Suitable for Class IIA, IIB, and IIC explosive gas environments;

3. Suitable for Zone 21 and Zone 22 locations in explosive dust environments;

4. Suitable for Class IIIA, IIIB, and IIC explosive dust environments;

5. Suitable for temperature classes T1 to T6;

6. Suitable for hazardous environments in petroleum extraction, refining, chemical processing, military applications, offshore oil platforms, tankers, defense industries, metal processing, and similar settings.